- I handle a wealth of material and weave various

- In compliance with the requirements of clients, we can cope with the short term delivery of numerous grades of products even in small quantities, not to speak of the mass production request. For example, you can select the weaving method among the plain weave, twill weave, and special weave. The weaving length can range from 30 meters to 500meters. Varieties of requests from clients will be handled in a versatile and flexible way. As to the kinds of raw material wire, you have a choice to fill the requirements on performance and functionability such as corrosion resistance and durability. Super-fine stainless steel wire is also available in our efforts to offer the convincing satisfaction to clients ahead of the times.

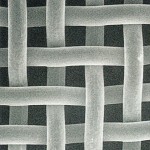

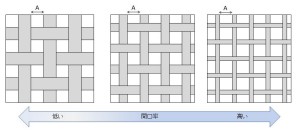

Plain weaving

| Warp wires keep each other acertain distance and so do weft wires.Warp and weft wires arecombined alternatingly in the weavJng operations.This is the basic weavlng method and the exactpassing size is obtainable. This type is used for the screen printing filter,shifting filter and general purpose filter. |

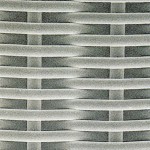

Twilled weaving

| Warp wires keep each other a certain distance and so do weft wires. They are combined alternatingly by getting over more than 2 wires. The bending or folding angle is rather large and relatively large diameter wire can be used. It has a longer service life than the flat weaving product and a higher number of mesh wires can be selected, to mention a few features. It is used for the sieve and filter for filtration with high mesh density. |

Plain dutch weaving

| This weaving method is in principle the same with the plain weaving, except for that the weft wires are arrayed in contact each other. Weaving pattern is like that of straw mat. Higher strengh is obtainable thereby and it is suitably used for reinforcement application. A larger number of meshes can be arranged for the wire diameter, and a fine filtration mesh size can be obtained. This weaving method is applied to the preparation of various filters for filtration operation. |

Twilled dutch weaving

| Dutch weaving is conducted in twill way, in which the warp wire gets over more than 2 weft wires. In comparison with other weaving methods, finer filtration mesh size can be prepared. Furthermore, the surface can be finished in smooth way. The prepared product is used in the filtration filters, etc., which is higher in mesh density, compared with the plain dutch weaving product. |

Five-heddle twilled weaving

| In this weaving method, the weft wire gets over 4 warp wires and then goes under 1 warp wire. The surface pattern and back pattern are different. |

Reversed plain weaving

| Weave the reverse of the relationship of horizontal and vertical lines of flat-woven mat. The excellent strength in the vertical direction, It is primarily used in applications that require resistance to the longitudinal direction of the conveyor or the like. It also suitable strainer like long and has excellent workability in the vertical direction. |

Reversed twilled ewaving

| Weave the reverse of the relationship of horizontal and vertical lines of Ayatatamio. I am suitable for environments that require strength and filtration accuracy than Reversed twilled ewaving. |

Other weaving methods

| In addition to the warp strand flat weaving and co-twisted wire weaving, in which the twisted wire is used, various weaving methods are available, as stated below, for selection upon your request. Reversed dutch weaving, reversed twilled dutch weaving, stranded twilled weaving, crimp weaving, lock crimp weaving, flat top weaving, ton cap weaving, tie rod weaving, twine weaving, lozenge pattern weaving, circular pattern weaving, herringbone weaving, wire conveyor net weaving, hexagonal pattern weaving, etc. |

- 各対応可能材質

- The material of the industrial wire mesh is centered stainless steel wire, copper alloy wire, but the manufacturing network is possible by the size of a material below. Please contact us once you relate to material not listed. Nickel alloy / Nickel-chrome wire / Lron wire / Iron chrome wire / Aluminum wire Copper wire / Molybdenum wire / Brass / Titanium wire and various other materials

- Corresponding size

- Manufacturing network size to width 2030mm, there is a track record up to 500m in length. We will also correspondence only for need can be provided on request. First of all, please contact us once.

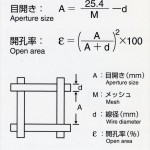

- Method of calculation

-

Mesh : The number of openings per lineal inch of wire cloth, measured from the center of wire. Open Area : The ratio of the area of the open spaces between the wire to the total area of a piece of wire cloth, expressed as a percentage.

- Properties and uses of stainless

-

Steel grade Properties and Uses SUS304 The most widely used stainless steel, as heat-resistant steel. High strength can be obtained by cold working of the intensity and processed wire spring, the wire rope. I used building materials, food equipment, general chemical equipment, nuclear power for. SUS304L It is possible to reduce the C-304, to improve the intergranular corrosion resistance. Corrosion-resistant system general, the same as the 304. SUS310S Oxidation resistance superior to SUS304, suitable for thermal applications. Since withstand up to 1035 ℃, used furnace material, such as in automobile exhaust emission control system. SUS316 The increasing amounts of Ni in 304, was added and Mo, to the chemical marine atmosphere, many types, there is a corrosion resistance superior to 304. Increase in strength due to cold working is inferior to 304, but I keep almost non-magnetic. SUS316L Which reduces the C 316, and improved the intergranular corrosion resistance. General corrosion resistance is the same as 316. SUS321 Which was added to the 304 Ti, enhanced the intergranular corrosion resistance. SUS410 I have good machinability and rusting resistance. For general use. Cutlery. Used knives, bolts, nuts, steam turbine blades, and jet engine parts. SUS410L Lower C content than SUS410, I am excellent workability. I used exhaust gas treatment equipment, boiler combustion chamber, and burner. SUS430 Excellent cold workability, corrosion resistance standard type of 18Cr steel, it has been used widely. Used car wiper arm material, kitchen equipment, building interior, and general household appliances.

- Types and Characteristics of Main Material

-

Type Properties and Uses Nickel200 In wrought of pure Ni general, there is excellent durability in corrosive media and a lot of good mechanical properties. Used manufacturing equipment for the food, caustic soda, chemicals and synthetic fibers, such as in aircraft, electrical and electro-mechanical parts. Inconel Under the trade name of Inco, a trademark of superalloy nickel-based. It is based on Ni, is divided into Inconel 600, Inconel 625 or the like of an alloy element content difference Fe, Cr, Nb, and Mo, and the like. I have oxidation resistance and high strength from low to high temperatures, the fatigue strength. I also excellent in corrosion resistance. Used parts space shuttle, nuclear industry, the turbine, aircraft engines, and high-quality automobile muffler. Incoloy825 It is excellent in corrosion resistance to acid stress corrosion cracking, crevice corrosion of the reducing-oxidizing both. Used chemical industry, acid production facilities, nuclear fuel reprocessing facilities, oil and gas oil field equipment, and marine and coastal plant. Monel400 In one of the Ni alloy, I have excellent workability there is strength. I have excellent corrosion resistance a wide range of sea water, acids, alkalis. Ocean desalination, petroleum refining parts, marine, etc. wide range of applications. Hastelloy Heat and corrosion-resistant alloy. Including Ni ・ Cr ・ Mo ・ Fe. Some, including Si, W, Cu is another. Used and waste treatment facilities, petrochemical relationship, and flue gas system. Carpenter Corrosion-resistant alloy of Ni-Fe-Cr, including Cu, and Mo. I have excellent corrosion resistance to general corrosion, crevice corrosion, pitting in the dissolution containing a wide range of acid. To be used in such as chemical and petrochemical industry manufacturing equipment and equipment parts. Brass Brass, called also brass (brass), an alloy of copper and zinc, zinc says of 20% or more. It has genus ductility and moderate intensity (65% copper, 35% zinc in general), casting, processing easy. I used and sieve, filter, and radio shielding. Titanium Be used (TW270) JIS1 species often in wire mesh. Excellent corrosion resistance in seawater in particular, used chemical equipment, oil refining equipment, paper making equipment.